Terminal Blocks: The Unsung Backbone of Reliable Industrial Wiring

Executive note: Terminal blocks are small, inexpensive components that dramatically improve reliability, safety and maintainability in electrical systems. Used in control cabinets, distribution boxes, junction enclosures and field terminals, modern terminal blocks support spring or screw connections, feed-through, pluggable modules, and integrated fusing. This article explores types, materials, mounting styles, safety standards, real-world applications, and procurement guidance — with reference to Olayksele’s terminal block solutions.

Executive Summary

Terminal blocks act as the discrete connection points within electrical systems. Their roles go beyond mere wire termination: they organize wiring, provide clear labeling, allow isolation and testing without disturbing neighboring circuits, and support modular replacements. Specifying the correct terminal block type — considering current rating, wire size, environmental exposure and mounting standards — reduces downtime, simplifies maintenance and supports safer installations. For industries ranging from renewable energy to factory automation, terminal blocks are a critical part of both design and operations.

Introduction

Though often overlooked in design documents, terminal blocks are central to ensuring clean, safe, and maintainable electrical installations. From DIN-rail screw terminals in PLC cabinets to waterproof feed-throughs in outdoor distribution boxes, terminal blocks provide the interface between field wiring and control electronics. Advances in materials, connection mechanisms and integrated accessories (e.g., markers, jumpers, fuses) have transformed terminal blocks into configurable system components rather than simple wire endpoints.

Types of Terminal Blocks

Screw-clamp Terminal Blocks

The traditional screw-clamp terminal uses a screw to tighten a metal plate against the conductor. They are robust, forgiving of multiple re-terminations, and are still widely used for power connections and heavy-gauge wiring.

Spring-cage (Push-in) Terminal Blocks

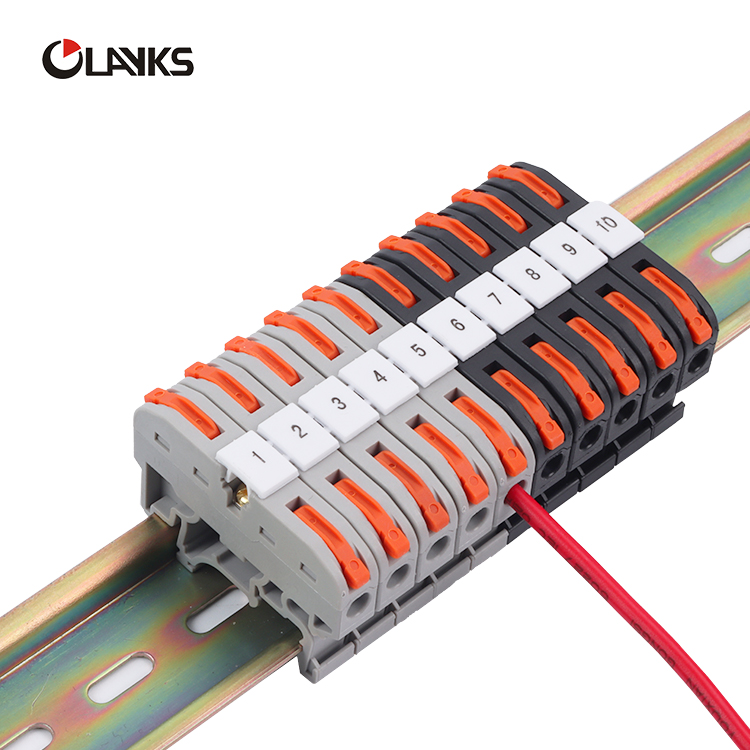

Spring-cage terminals use a spring mechanism to clamp the conductor. They provide tool-free insertion, consistent contact force, and are preferred in high-density cabinets and automated assembly contexts where speed and vibration resistance matter.

Feed-through Terminal Blocks

Feed-through blocks offer a straight-through connection from one side of the terminal to the other—ideal for junctions where a wire passes through an enclosure with minimal interruption.

Pluggable / Removable Terminal Blocks

These allow a section of wiring to be disconnected quickly without de-terminating every conductor. Pluggable blocks speed replacement and enable pre-wiring of field harnesses.

Multi-level & Multi-conductor Terminal Blocks

Used when space is limited, multi-level blocks stack multiple connections vertically to maintain circuit separation while increasing density.

Fuse & Disconnect Terminal Blocks

Some terminal blocks integrate fuse holders, disconnect switches, or test points—ideal for serviceable protection inside distribution boxes.

Specialty Types

Including PCB-mounted terminals, barrier terminal blocks, high-voltage isolation terminals, and waterproof IP-rated feed-through blocks suitable for outdoor or marine enclosures.

Materials & Construction

Terminal blocks need both electrical conductivity and mechanical durability. Typical materials include:

- Conductive parts: Copper alloys (often tin- or nickel-plated) or brass for low resistance and corrosion resistance.

- Insulators: Polyamide (PA66), PBT, or high-performance thermoplastics that resist heat, chemicals and track creeping.

- Sealing materials: For outdoor or IP-rated blocks, EPDM gaskets, silicone seals or potting compounds are used to prevent moisture ingress.

Plating and surface finish matter: tin plating protects against oxidation; nickel is used for high-temperature or soldered terminations. Material selection should follow application requirements (temperature, humidity, UV exposure, corrosive atmosphere).

Design Considerations & Mounting

When choosing terminal blocks, consider the following design and mounting factors:

- Mounting style: DIN-rail (TS35) is the industry standard for enclosure-mounted blocks. PCB-mount blocks are used inside devices.

- Current & voltage ratings: Blocks must exceed expected operating current and voltage with margin for inrush currents.

- Wire cross-section: Specify the AWG/mm² range and consider ferrules for stranded conductors.

- Pitch and density: Higher density reduces panel area but increases wiring complexity.

- Access for maintenance: Pluggable designs help reduce MTTR (mean time to repair).

- Marker & labeling options: Integrated marking slots, printed labels or clip-on markers for traceability.

Safety, Standards & Compliance

Terminal blocks are covered by various international standards that address their mechanical, electrical and flammability properties:

- IEC 60947 / IEC 60999: Standards covering electrical connectors and terminals.

- UL 1059: Standard for terminal blocks in North America (current-carrying capacity and temperature rise).

- IEC 60529 (IP rating): For ingress protection of enclosed blocks or feed-throughs.

- V-0 / UL94: Flammability rating for insulating plastics.

- RoHS / REACH compliance: Material restrictions and chemical safety.

End-users should require test reports showing temperature-rise at rated current, dielectric strength, and third-party safety approvals when specifying blocks for critical systems.

Applications & Use Cases

Factory Automation & Control Panels

Terminal blocks are ubiquitous in PLC cabinets, connecting sensors, actuators and power rails. Spring-cage terminals reduce wiring time during high-volume installations.

Renewable Energy & Distribution Boxes

In solar combiner boxes, terminal blocks gather multiple string connections; waterproof feed-through blocks enable secure connections in outdoor distribution boxes. Blocks with integrated fuses or disconnects simplify string protection.

Transportation & Rail

Vibration-resistant spring or screw blocks with high retention forces are used in rail and vehicle electronics.

Marine & Offshore

Marine-grade terminal blocks use corrosion-resistant metals and sealed housings for reliable electrical joints in salty, humid environments.

Building Automation & HVAC

Terminal blocks simplify connecting thermostats, sensors, and actuators across multiple floors and simplify service routines for building operators.

Telecommunications & Data Centers

High-density terminal blocks are used for power distribution and grounding, especially where clear labeling and modular replacement are required.

Installation & Maintenance Best Practices

Proper termination and maintenance are essential for long-term reliability:

- Use the correct tool and torque: Manufacturer-specified torque prevents under- or over-tightening which can cause hot spots or conductor damage.

- Use ferrules for stranded conductors: Prevents strand splaying and ensures repeatable contact.

- Observe polarity and phase labeling: Marking reduces wiring errors and speeds troubleshooting.

- Inspect periodically: Check for corrosion, loosening due to thermal cycling or vibration, and replace damaged blocks promptly.

- Record maintenance data: Keep torque values, replacement dates, and part numbers for critical connections.

Testing & Quality Assurance

High-quality terminal blocks undergo testing for:

- Mechanical endurance (repeated terminations)

- Temperature rise at rated current

- Dielectric strength and insulation resistance

- Vibration and shock resistance

- Corrosion resistance (salt spray for marine products)

Request manufacturer test reports and certification marks before bulk procurement, and where possible, witness factory testing for critical deployments.

Olayksele Terminal Blocks — Product Highlights

Olayksele’s terminal block offerings (referenced on their terminalBlocks product pages) include DIN-rail feed-through, pluggable models, and IP-rated feed-throughs for outdoor enclosures. Key features often highlighted by the manufacturer include:

- Modular design compatible with DIN-rail mounting

- High-current variants and multi-level high-density blocks

- Options for integrated fusing, disconnects, and test points

- IP-rated feed-throughs for waterproof distribution boxes

- Accessory ecosystem: markers, bridges/jumpers, end stops, and cover plates

Specifiers should consult product datasheets for exact electrical ratings, compatible wire sizes, and accessory part numbers.

Market Trends & Demand Drivers

Several trends are shaping the terminal block market:

- Modularity & serviceability: Demand for pluggable and modular solutions that reduce downtime.

- Higher density: Compact control panels push for denser pitch and multi-level designs.

- Smart factory integration: Terminal blocks with integrated sensors or monitoring terminals are emerging for predictive maintenance.

- Outdoor and renewable deployments: IP-rated feed-throughs are increasingly specified for combiner and distribution boxes.

Case Studies

Industrial Conveyor Control Upgrade

A manufacturer standardized on spring-cage pluggable terminal blocks across 40 control panels. The result: wiring time decreased by 30% and panel rebuilds were completed faster with fewer wiring errors.

Solar Plant Combiner Retrofit

A 50 MW solar farm retrofitted combiner boxes with IP67 feed-through terminal blocks with integrated fusing. This eliminated several field failures due to water ingress and simplified string-level maintenance.

Marine Communications Hut

Marine-grade terminal blocks with nickel-plated conductors and sealed housings extended the mean time between failures on a coastal communications site operating in a salt environment.

Procurement Guide & Checklist

When procuring terminal blocks, include the following checklist in RFQs:

- Electrical ratings (AC/DC voltage, continuous current, short-circuit withstand)

- Wire cross-section range and ferrule compatibility

- Mounting style (DIN-rail, PCB, panel) and pitch

- Environmental ratings (IP, salt spray, temperature range)

- Accessory availability (jumpers, fuses, markers)

- Type tests, UL/IEC approvals, and factory test reports

- Lead time, MOQ, and spare parts policy

Sustainability & End-of-Life Considerations

Designing for sustainability means selecting materials and suppliers that support recycling, long life and refurbishment. Consider:

- Materials that are recyclable and free from hazardous additives

- Design for disassembly so metal parts can be separated from plastics

- Supplier take-back programs for large-scale replacement cycles

Future Innovations

Look for:

- Terminal blocks with embedded sensing (temperature, micro-looseness detection)

- Tool-assisted termination verification (torque logging)

- Lower-pitch, higher-density solutions using new polymer and conductor technologies

- Improved IP-rated feed-throughs that integrate surge protection and monitoring