Waterproof Switches, Waterproof Sockets & Distribution Boxes — Reinventing Outdoor Electrical Safety

Summary: Waterproof switches and waterproof sockets, when integrated properly into robust distribution boxes, form the frontline defense for outdoor and harsh-environment electrical systems. From residential garden lighting to industrial distribution, these products prevent ingress, improve safety, and enable longer service life. This feature explores technologies, product types, installation best practices, distribution box integration, market trends, top industry players, and buying guidance.

Executive Summary

As infrastructure expands outdoors — smart lighting, EV charging, solar farms, marine facilities, and public spaces — demand for waterproof electrical components rises sharply. Waterproof switches and waterproof sockets rated IP65–IP68, combined with waterproof distribution boxes (often described as outdoor electrical enclosures or weatherproof distribution boxes), reduce failure risks from moisture, dust, and corrosion. When specified correctly and installed with attention to sealing, cable glands, and surge protection, these components help lower maintenance costs and increase system uptime.

Introduction

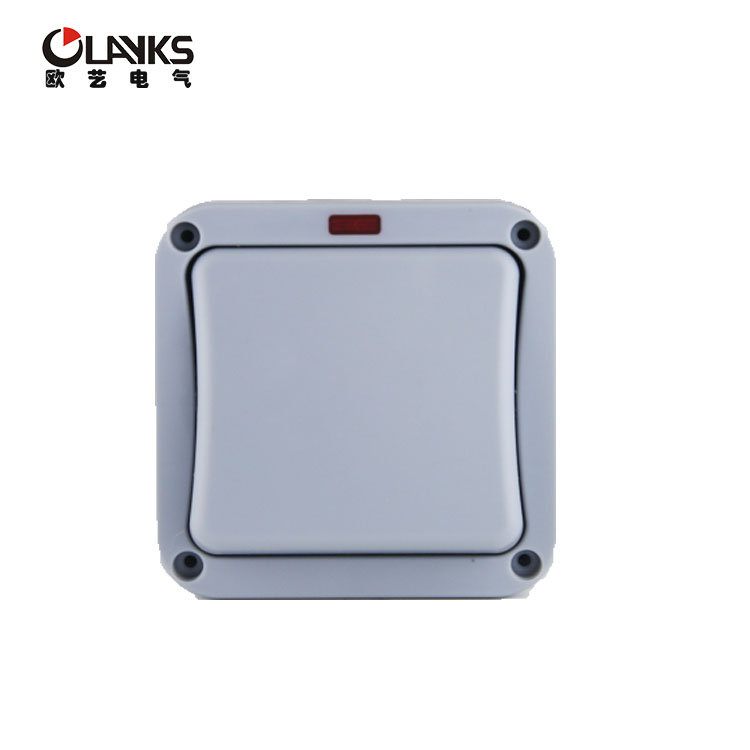

Water intrusion and dust contamination are among the leading causes of outdoor electrical faults. Traditional indoor-rated switches and sockets fail quickly outside. Manufacturers such as Olayksele specialize in purpose-built waterproof switches, waterproof sockets, and distribution boxes designed to maintain operational integrity even in rain, snow, salt spray, and dusty environments. This article covers the technical foundations and practical guidance for engineers, specifiers, and procurement teams.

Definitions & Key Terms

Waterproof Switch: A switch with an enclosure, sealing, and materials designed to prevent water ingress to the switching mechanism, rated by an IP code (often IP65/66).

Waterproof Socket: A power outlet (AC or DC) designed with sealing and protective covers to allow safe outdoor power connections.

Distribution Box (Distribution Box / Distribution Enclosure): An enclosure that houses circuit protection devices, terminal blocks, cable entries, and sometimes communications or monitoring devices — used to distribute power in building, industrial, and renewable systems.

Ingress Protection (IP) Rating: International standard (IEC 60529) describing levels of protection against solids (1st digit) and liquids (2nd digit). Examples: IP65 (dust tight, water jets), IP66 (powerful water jets), IP67 (temporary immersion), IP68 (continuous immersion).

Applications of Waterproof Switches & Waterproof Sockets

Outdoor Lighting & Urban Infrastructure

Waterproof switches and sockets are vital for streetlights, park lighting, landscape lighting and architectural illumination. They protect control and power points from rain, snow and dust while allowing maintenance crews to access power points safely.

Renewable Energy — Solar & Wind

Solar combiner boxes, inverter junctions, and string-level disconnects benefit from waterproof connectors and sockets. Distribution boxes used at inverter stations regularly incorporate waterproof switches/sockets for commissioning and maintenance tasks.

Marine & Offshore

Salt, humidity, and splash make marine applications harsh. Waterproof sockets, especially those built to IP66/IP67 with corrosion-resistant materials, are indispensable on ships, docks and offshore platforms.

Industrial & Process Plants

Chemical plants, food processing and outdoor manufacturing lines require rugged waterproof devices. Distribution boxes with appropriate IP/NEMA ratings protect critical circuits and instrumentation.

Public & Commercial Spaces

EV charging areas, outdoor kiosks, public Wi-Fi nodes, and digital signage use waterproof sockets and distribution boxes for safe public access and durability.

Specialty Vehicles & Equipment

Sprinkler trucks, road maintenance vehicles, and mobile concert equipment often use waterproof sockets and distribution boxes to protect power connections against spray and dust.

Product Designs & Types

Switch Types

Waterproof switch designs include rocker switches, toggle switches (sealed), momentary pushbuttons with gasket seals, and rotary selector switches within sealed housings. Many include protective covers or boot seals and are available in single-pole, double-pole, and multi-gang forms.

Socket Types

Sockets include outdoor-rated AC receptacles with spring-loaded covers, waterproof IEC connectors for equipment, DC quick-disconnect sockets for LED or solar equipment, and specialized marine sockets. Sockets can be lockable, weather-sealed, and incorporate inbuilt shutters for safety.

Distribution Boxes

Distribution boxes integrate terminal blocks, DIN-rail breakers, SPDs (surge protective devices), and sometimes monitoring modules. They come in polycarbonate, ABS, GRP (glass-reinforced polyester) or metal (stainless steel / aluminum) bodies depending on environmental needs.

Combination Units

Many manufacturers offer combined distribution boxes with built-in waterproof switches and sockets — ideal for field service points. These often include hinged covers, keyed locks and removable inner modules for rapid replacement.

Materials, Sealing & IP Ratings

Material selection affects UV stability, mechanical strength and corrosion resistance.

- Polycarbonate (PC): High impact, good UV performance when formulated with stabilizers; commonly used for transparent covers and housings.

- ABS/PC blends: Cost-effective and impact resistant for many outdoor enclosures.

- GRP/FRP: Excellent corrosion resistance in chemical or marine environments.

- Stainless steel / powder-coated aluminum: Used where mechanical strength and long-term corrosion resistance are critical.

Sealing strategies include molded gaskets, O-rings on covers, sealed cable glands with proper torque, and potting for internal modules where necessary. Extreme applications may call for IP68 or even specialized submersible designs.

Installation & Maintenance Best Practices

Correct installation is essential to achieve stated IP ratings and long service life.

- Cable Glands & Strain Relief: Use manufacturer-specified glands sized to cable OD. Tighten per torque guidance and ensure gland seals compress evenly.

- Sealing Surfaces: Clean and inspect gasket grooves; remove dirt and debris before closing the cover. Replace gaskets periodically based on UV and chemical exposure.

- Correct Mounting Orientation: For hinged covers, mount so water run-off occurs away from seams and gland entries whenever possible.

- Proper Termination: Use the correct screwdriver torque for terminal screws and tighten per spec to prevent loosening under vibration.

- Surge Protection: Install SPDs at distribution points to protect sockets and internal electronics from transients.

- Labeling & Documentation: Label circuits, record torque values and installation photos for maintenance records.

Routine inspections — check gasket condition, look for corrosion at terminals, verify that covers latch correctly — extend the product life and reduce failures.

Standards & Certification

Key standards and certifications help ensure safety and interoperability:

- IEC 60529 (IP code) — Ingress protection classification for dust and water.

- EN/IEC 60669 — Switches for household and similar fixed electrical installations.

- IEC 60884 / BS 1363 — Socket outlet standards by region.

- UL 50 / UL 50E — Enclosure standards (North America) for electrical equipment.

- IEC 61439 — Low-voltage switchgear and controlgear assemblies (for distribution boxes/panels).

- Marine & ATEX — For explosive atmospheres or marine environments, special approvals are used.

Buyers should require evidence of third-party testing: salt spray, UV aging, thermal cycling, and IP ingress tests performed to accredited lab protocols.

Distribution Boxes — How Waterproof Switches & Sockets Integrate

Distribution boxes act as the deployment point for waterproof switches and sockets in the field. Typical integration patterns:

- Service Access Module: A compartment containing waterproof sockets for commissioning, testing and temporary loads.

- Control Module: Housings that contain sealed switchgear, local isolators and control switches for localized equipment.

- Monitoring Module: A subcompartment hosting telemetry, humidity sensors and power meters — designed with sealed cable entries and filtered vents when necessary.

Designers should allow space for terminal blocks, spare gland positions, and modular DIN-rail mounted components to simplify future upgrades.

Selected Case Studies

1. Coastal Solar Farm — Northern Europe

Problem: Salt spray and high humidity causing repeated failures in outdoor junctions.

Solution: Replace indoor-rated sockets and junctions with IP66 waterproof sockets, stainless steel distribution boxes and UV-stabilized polycarbonate covers. Result: 90% reduction in corrosion-related maintenance visits, improved system uptime and longer warranty performance.

2. Waterfront Marina — East Asia

Problem: Shore power sockets and lighting caused tripping and corrosion.

Solution: Install marine-grade waterproof sockets with keyed covers integrated into IP67 distribution boxes, with dedicated SPDs and residual-current protection. Result: Safer shore power, fewer incidents, higher satisfaction from marina tenants.

3. City Smart Lighting Upgrade — North America

Problem: Frequent lamp failures and high O&M on urban lighting network.

Solution: Standardize distribution boxes with built-in waterproof sockets for local tools, sealed switches for section control, and embedded monitoring modules. Result: Reduced truck rolls, faster fault isolation and energy savings through adaptive dimming enabled by robust controllers.

Market Trends & Demand Drivers

Key drivers:

- Growth of outdoor electrification (EV charging, public Wi-Fi, outdoor retail kiosks).

- Expansion of renewable energy projects requiring durable field connections.

- Urban infrastructure modernization and smart city investments.

- Increased regulatory focus on safety — e.g., requirements for rapid shutdown and arc fault detection in PV installations.

Market trend: buyers increasingly seek integrated solutions (distribution box + waterproof sockets + monitoring) to simplify procurement and reduce compatibility risks.

Industry Top 10 (Waterproof Switches, Waterproof Sockets & Distribution Boxes)

Below is a representative list of leading companies active in waterproof electrical hardware and distribution solutions. The list blends globally known electrical manufacturers and specialized outdoor enclosure suppliers (order is not a strict ranking).

- Olayksele — Specializes in waterproof sockets, switches, and distribution boxes for outdoor and industrial applications (global supply and customization). (olayksele.com)

- Schneider Electric — Wide portfolio including outdoor-rated switches, enclosures and power distribution equipment.

- ABB — Industrial electrical products with solutions for outdoor and marine environments.

- Siemens — Offers robust outdoor switchgear, enclosures and control solutions.

- Legrand — Known for outdoor sockets, waterproof covers and architectural electrical solutions.

- Hubbell — Durable outdoor receptacles, industrial waterproof connectors and distribution equipment.

- Weidmüller — Terminal blocks, connectors and waterproof enclosures for industrial automation.

- TE Connectivity — Specialized waterproof connectors and sealed socket systems for harsh environments.

- Eaton — Power distribution products and outdoor-rated protective devices.

- Rittal / E+H groups (enclosure specialists) — Durable enclosures and distribution cabinets with waterproof variants.

Note: This list is illustrative. For procurement, compare product specs (IP rating, UV resistance, material) and request third-party test reports.

Procurement & Specification Checklist

When specifying waterproof switches, waterproof sockets, or distribution boxes, check the following:

- IP/NEMA rating required for the site (exposure to jets, immersion, salt spray).

- Material suitability (UV, chemical exposure, mechanical impact).

- Temperature range and thermal management if housing power electronics.

- Terminal capacity, conductor sizes and short-circuit rating.

- Surge protection and residual-current devices as required by code.

- Accessibility for maintenance, spare parts and module replacement.

- Communication/monitoring requirements (e.g., telemetry, remote status).

- Certifications (CE, UL, IEC, marine, ATEX if necessary).

Sustainability & Lifecycle Considerations

Longevity reduces lifecycle environmental impact. Choose materials that resist UV and corrosion to minimize replacements. Opportunities for sustainability:

- Design for disassembly — enable recycling of metals and separation of plastics.

- Use of recyclable or bio-based polymer alternatives where suitable.

- Supplier take-back or refurbishment programs for large fleets of distribution boxes.

- Energy-efficient manufacturing and reduced packaging for bulk deployments.

Future Outlook & Emerging Technologies

Developments to watch:

- Smart enclosures: Distribution boxes with built-in IoT telemetry, humidity/temperature alerts and OTA firmware updates.

- Advanced materials: Nanocomposite coatings to reduce fouling and enhance UV resistance.

- Integrated safety: Arc-fault detection and DC fast-shutdown modules integrated into the distribution box.

- Secure remote management: Encrypted telemetry and predictive maintenance platforms to minimize O&M costs.

These trends converge: waterproof mechanical design + digital intelligence = safer, longer-lasting field systems with lower total cost of ownership.

About Olayksele

Olayksele develops waterproof switches, waterproof sockets and distribution boxes tailored for outdoor, industrial, and renewable energy applications. Their product range includes IP65–IP68 sockets, GWP series waterproof sockets, and modular distribution boxes with options for DIN-rail components, SPDs and monitoring modules. Reach Olayksele via their product pages for datasheets and customization.