Overview

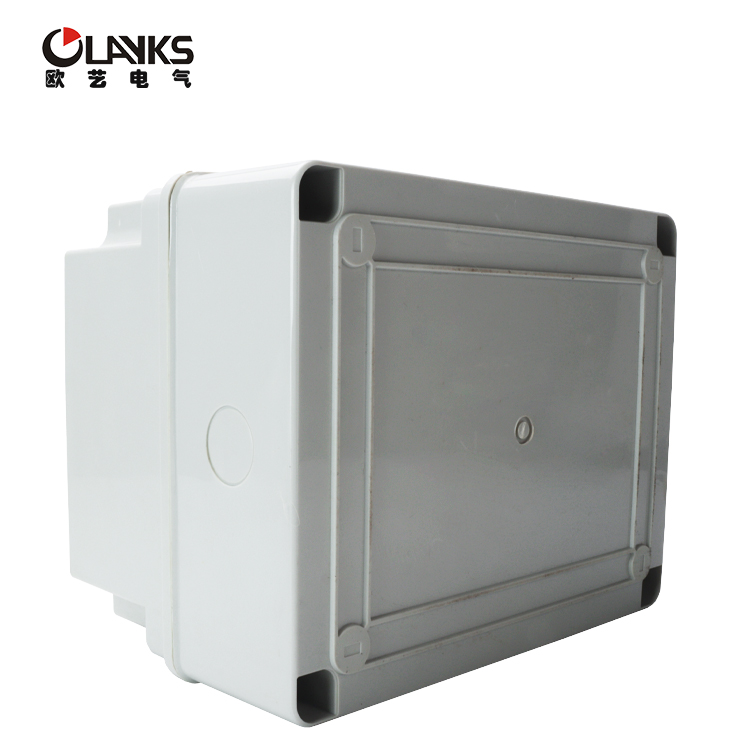

The industrial sector has witnessed a groundbreaking advancement with the introduction of our new line of electrical enclosures, setting unprecedented standards for robustness, versatility, and reliability in harsh environments.

These enclosures represent a significant leap forward in protective housing technology, combining innovative design with superior materials to deliver solutions that meet the most demanding industrial requirements while maintaining flexibility for diverse applications.

Key Features

The new electrical enclosure series incorporates several industry-first features that distinguish it from conventional solutions:

- Enhanced Durability: Engineered to withstand extreme temperatures (-40°C to +120°C) and harsh environmental conditions

- Modular Design: Flexible configuration options with easy-to-install mounting systems

- Superior Protection: IP66/IP67 rated for dust and water ingress protection

- Smart Integration: Pre-configured options for IoT sensor integration and remote monitoring

- Safety First: Integrated grounding systems and arc-flash protection

- Easy Maintenance: Tool-less access panels and clear labeling systems

Industrial Applications

These versatile enclosures are designed to meet the needs of multiple industries:

- Oil & Gas: Explosion-proof versions for hazardous areas

- Renewable Energy: Weather-resistant solutions for solar and wind installations

- Manufacturing: Durable enclosures for factory automation

- Transportation: Vibration-resistant designs for rail and marine applications

- Utilities: Tamper-proof solutions for outdoor substations

"This new enclosure system represents a paradigm shift in how we protect critical electrical components. The combination of durability and flexibility solves problems we've struggled with for years."

Advanced Materials

The enclosures utilize cutting-edge materials technology:

- Composite Alloys: Lightweight yet stronger than traditional steel

- Corrosion Resistance: Special coatings for saltwater and chemical exposure

- Thermal Management: Heat-dissipating materials for high-power applications

- UV Protection: Sun-resistant polymers for outdoor longevity

- Recyclable: Environmentally conscious design with 95% recyclable materials

Certifications

The product line meets or exceeds all major international standards:

- UL 508A (Industrial Control Panels)

- NEMA 4X (Corrosion Resistance)

- IEC 60529 (IP Ratings)

- ATEX Zone 1/21 (Explosive Atmospheres)

- CE, RoHS, REACH (European Compliance)

Global Availability

The new electrical enclosure solutions are now available worldwide through our authorized distributors, with regional stock maintained for rapid delivery. Custom configurations can be delivered within 2-4 weeks depending on complexity.

Technical specifications, CAD models, and configuration tools are available on our website, along with a network of application engineers ready to assist with project-specific requirements.