1. Introduction

The PCT Connection Series represents the latest generation of compact splicing wire connectors designed to simplify electrical wiring, ensure long-term reliability, and improve installation efficiency. These connectors eliminate the need for traditional twisting, crimping, or soldering methods, offering a clean, safe, and tool-free solution for both professional electricians and DIY users.

Developed with precision engineering, the PCT Series features a transparent housing, lever-operated terminals, and a highly conductive copper alloy interface. This documentation provides comprehensive technical details, including materials, specifications, installation processes, and performance testing results.

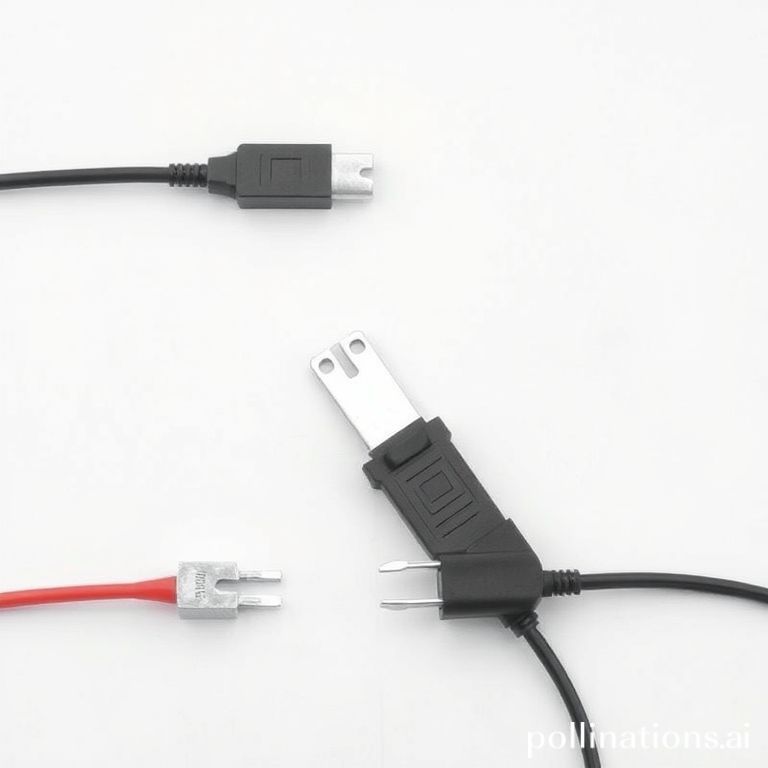

2. Design Overview

The PCT connector is built on a modular design concept. Each unit contains a conductor housing, spring clamp mechanism, and lever lock system. The compact geometry allows dense wiring in confined spaces while maintaining accessibility and flexibility.

- Transparent Housing: Enables visual inspection of the wire position.

- Lever Mechanism: Provides quick open/close operation without tools.

- Spring Clamp: Ensures stable electrical contact under vibration or temperature change.

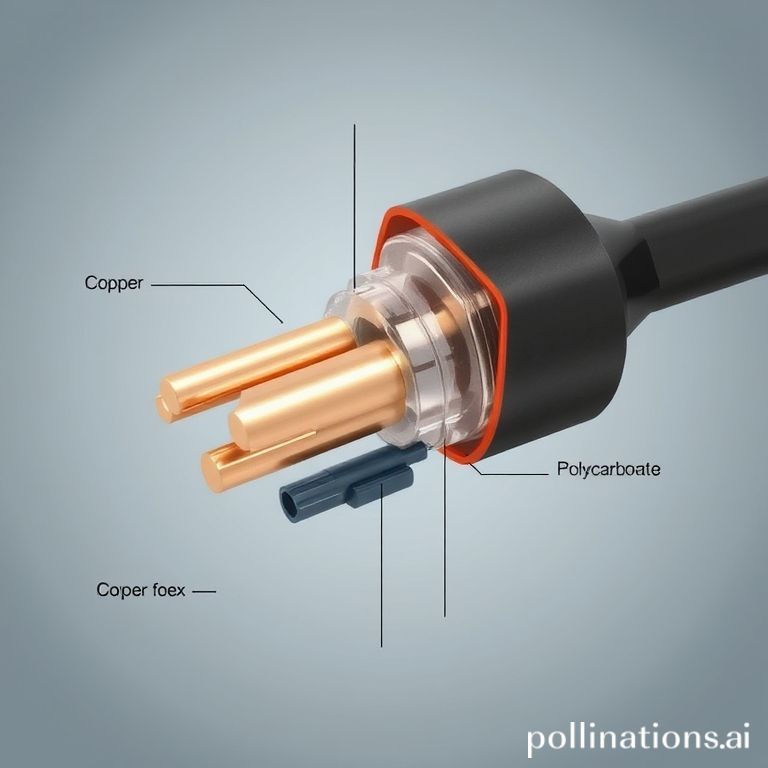

3. Material Composition

Each PCT connector is composed of high-performance polymers and metal alloys designed for durability and fire resistance:

- Housing: Flame-retardant polycarbonate (UL94 V-0)

- Conductor: Tin-plated copper alloy for maximum conductivity

- Lever: Reinforced nylon PA66

- Spring: Stainless steel for mechanical stability

All materials comply with RoHS and REACH directives, ensuring environmental safety and minimal carbon footprint during production.

4. Technical Specifications

| Parameter | Value |

|---|---|

| Rated Voltage | 450V |

| Rated Current | 32A |

| Wire Range (Solid) | 0.2–4.0 mm² |

| Wire Range (Flexible) | 0.14–4.0 mm² |

| Operating Temperature | -40°C to +105°C |

| Flame Retardant Grade | UL94 V-0 |

| Durability | >100 connection cycles |

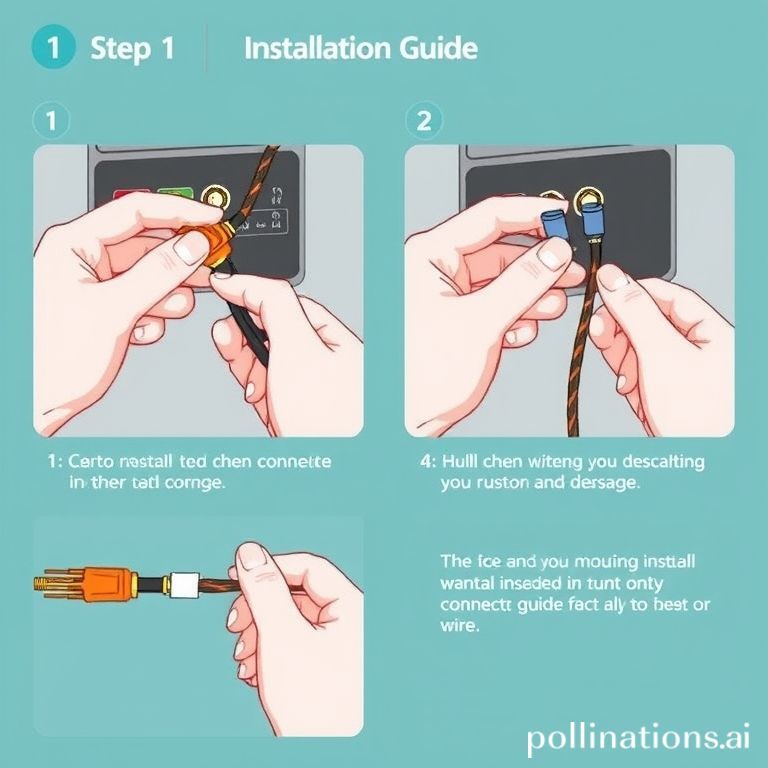

5. Installation Guidelines

Installing a PCT connector is intuitive and requires no special tools:

- Lift the orange lever to open the terminal.

- Insert the stripped wire (8–10 mm exposed length).

- Press the lever down to lock the wire.

- Visually confirm the wire’s position through the transparent body.

The connection can be re-opened for maintenance or testing without damaging the wire or housing.

6. Performance & Testing

PCT connectors undergo multiple quality tests, including mechanical endurance, dielectric strength, and thermal stability assessments. Each product is factory-tested to ensure compliance with international safety standards.

- Dielectric strength test: 2.0kV for 60s

- Vibration resistance: IEC 61373

- Temperature rise test: <2°C at 32A load

7. Applications

The versatility of PCT connectors allows them to be used across a wide range of applications:

- Lighting systems and LED installations

- Household wiring and renovation

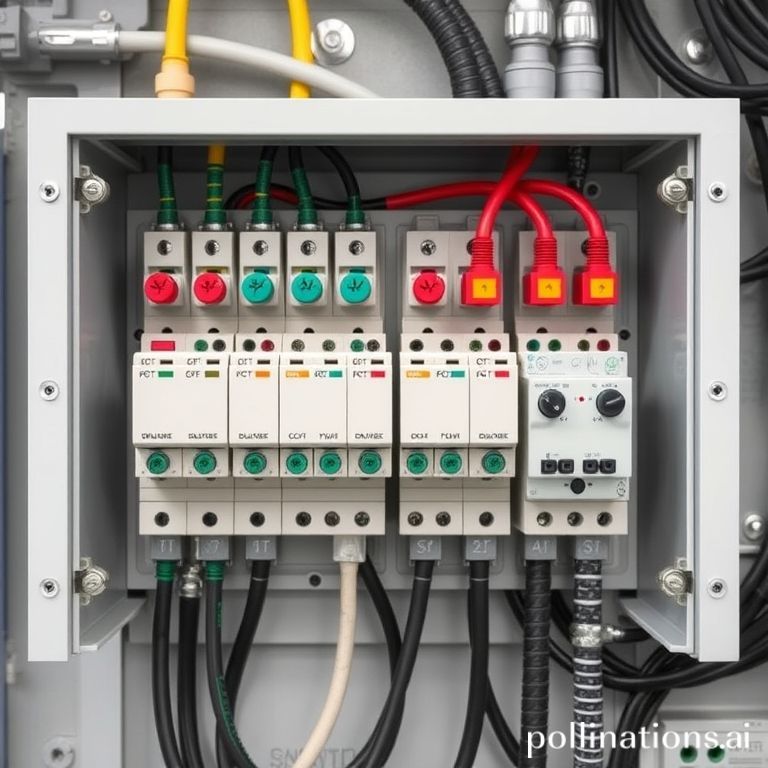

- Industrial control cabinets

- HVAC systems

- Automotive wiring prototypes

8. Comparison with Other Connectors

Compared to screw or crimp terminals, the PCT Series offers clear advantages:

- Faster installation: Up to 70% time savings.

- Reusable: No wire damage during removal.

- Compact: Saves up to 40% space in junction boxes.

- Safety: Built-in insulation and no loose screws.

9. Safety & Compliance

The PCT Connection Series complies with multiple international safety standards:

- CE (Conformité Européenne)

- UL (Underwriters Laboratories)

- TÜV Rheinland

- IEC 60998 & IEC 60947

10. Future Developments

Future generations of the PCT series aim to integrate smart monitoring features, such as embedded temperature sensors and current flow detection via IoT connectivity. These advancements will enable predictive maintenance and enhanced energy management for smart buildings and industrial automation systems.

11. Summary

The PCT Connection Series Compact Splicing Wire Connectors embody innovation in electrical interconnection technology — blending safety, speed, and sustainability. With ongoing improvements in materials and digital integration, they remain a top choice for modern wiring solutions in both residential and industrial contexts.